Weld quality is critical to the strength of a ship’s hull.

That’s why the team at Seaspan’s Vancouver Shipyards is implementing new robotic welding technology across the construction process, starting in the panel shop and the block assembly shop.

The new machinery is empowering skilled trades employees to do their best work more safely and efficiently and is part of Seaspan’s overall efforts to drive innovation in Canadian shipbuilding.

“Technically, robotic welding has been here for some time now,” explains Vincent Mak, Welder Chargehand at Vancouver Shipyards. “In terms of semi-automated technology, we’ve already been using a PEMA gantry welder in the sub-assembly shop as well as utilizing Submerged Arc Welding (SAW) and Bug-O systems. With this new equipment, we’re taking another step into the future and modernizing the entire construction process.”

Before the new equipment could be put to work at Vancouver Shipyards, Vincent and other members of the steel team travelled to Denmark for Factory Acceptance Testing at Inrotech, ensuring everything met Seaspan’s standards before shipment.

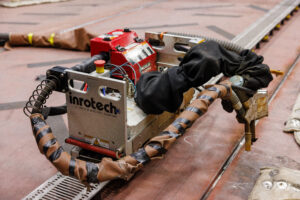

The equipment, which was installed in July, includes two Inrotech systems designed for different applications.

In the panel shop, the Inrotech Classic is used primarily for fillet welding on T-beams. In the block assembly shop, the more advanced Inrotech Crawler is used for groove welds, where steel plates are butted together to form long structural seams.

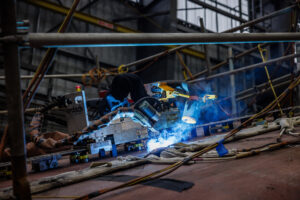

The Inrotech robotic crawler is being used in the block assembly shop to help weld the future polar icebreaker

The Inrotech Classic in the panel shop uses more basic technology. It can detect a seam, but the weld size needs to be input or programmed by an employee.

What sets the Inrotech Crawler apart is its 3D laser scanning capability. Unlike manual welding, where a person would adapt in real time to variations in a seam, the crawler scans and assesses the joint and only proceeds if the weld can meet weld procedure specifications. The scan will take consideration of the variances and plan/weld accordingly within tolerance.

“If it doesn’t think it can do a proper weld, it won’t do it,” Vincent says. “That’s actually a positive from a quality control standpoint. It might mean we need to adjust the fit of the plates or the way we need to sequence welds prior, but the end result is a weld that meets our standards.”

The Inrotech Crawler in the block assembly shop completed its first job in September — but introducing the new equipment didn’t just mean plugging it in. Vincent worked with the steel team to develop new weld procedures and qualification tests for the machines, also working closely with governing bodies including the Canadian Welding Bureau (CWB) and Lloyd’s Register, as well as obtaining customer approval.

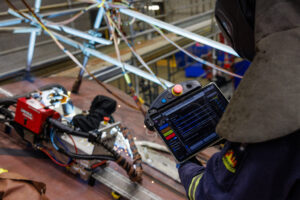

“There’s a different process to prepare for robotic welding compared to manual welding,” Vincent explains. “But welders are still essential. A qualified welder supervises the machine, reviews its work and decides when a job needs a human touch instead. If the variances are too high, a welder needs to know what to look for and how to fix it whether it be to add a weld or another modification to the seam.”

A Seaspan welder operates the new equipment

Both new machines are part of a subset of robots referred to as collaborative robots, or “cobots” that are intended to be actively used alongside a human operator. Finding the balance between automation and human craftsmanship and knowledge is central to how the new technology is being used in the yard.

“When the Inrotech Crawler completed its first job in September, one of the biggest surprises was the positive reception from the workforce,” says Vincent.

“Honestly, I expected more pushback. But most folks have been very supportive. We have so much welding work to do, especially with work on the polar icebreaker underway. The new equipment is being seen as a tool rather than a replacement for skilled welders.”

One of the key differences between a human-made, manual weld and a robotic weld is that a worker will typically start and stop several times with lots of re-adjusting, while a robotic welder can weld continuously. Building this efficiency is key as the welding workload continues to increase, with both JSS2 and the heavy polar icebreaker currently under construction at Vancouver Shipyards.

Inrotech crawler being utilized to weld steel blocks for the future heavy polar icebreaker under construction for the Canadian Coast Guard

“As projects like the Multi-Purpose Icebreakers (MPI) move forward, we continue to search for automation solutions while fully optimizing the tools we already have. Planning is key to automation success; looking ahead at the builds and sequencing to fully use the equipment at each stage. There’s an amazing opportunity here to work together across planning, engineering, production and quality teams to keep moving automation and efficiency forward, especially on future projects.” Richard Leech, Director, Manufacturing at Vancouver Shipyards, said.

Robotic and semi-automatic welding systems, including Bug-O machines are increasingly used to improve ergonomics and efficiency. “There’s been a real cultural shift,” says Vincent. “More people want to learn mechanical and semi-automatic welding. Compared to three years ago, semi-auto welding has increased significantly over manual welding, especially on projects like JSS2. It’s faster, more consistent, and easier on the body — especially in tight or awkward spaces.”

As Vancouver Shipyards continues to modernize, robotic welding is helping to improve quality, consistency and safety while creating new learning opportunities for skilled tradespeople.

“This technology doesn’t replace welders,” Vincent emphasizes. “It raises the bar. And our team is rising to meet it.” By combining advanced automation with the expertise of our workforce, Seaspan is driving innovation and building the skills needed for the future of Canadian shipbuilding.