WE BUILD SHIPS, WE REPAIR SHIPS, WE CONVERT SHIPS.

Located on the Pacific Northwest Coast, Seaspan Shipyards operations include Vancouver Shipyards, Vancouver Drydock and Victoria Shipyards. As a result of its diversity and capacity, Seaspan Shipyards is unique in its ability to provide a complete range of shipyard services including new construction, conversion, refit, repair, life-cycle maintenance and refurbishment work for naval, research and commercial vessels including cruise-ships, deep-sea vessels and submarines.

What We Do

Shipbuilding

At Seaspan’s Vancouver Shipyards, located in North Vancouver, Seaspan is building large non-combat vessels for the Canadian Coast Guard and Royal Canadian Navy under Canada’s National Shipbuilding Strategy (NSS).

Repair, Refit, and Conversion

Seaspan’s Victoria Shipyards, located in the Government of Canada owned Esquimalt Graving Dock, and Vancouver Drydock, located on the North Shore, provide repair, refit, and conversion work for a wide range of government and commercial clients.

Shipyards

Vancouver Shipyards

THE PRIME SHIPBUILDING SITE FOR BUILDING THE LARGE COMPLEX NON-COMBAT VESSELS UNDER CANADA’S NATIONAL SHIPBUILDING STRATEGY PROGRAM (NSS).

Seaspan Shipyards is proud to be Canada’s long-term, strategic shipbuilding partner for the Canadian Coast Guard and Royal Canadian Navy under the NSS. The NSS is a nation-building effort to create a sustainable Canadian shipbuilding industry, secure long-term job opportunities and build the next generation of ships for the Canadian Coast Guard and Royal Canadian Navy. Through its NSS–related work, Seaspan Shipyards is leading the redevelopment of our domestic shipbuilding industry on the West Coast and delivering on the promise of ships built in Canada, by Canadians.

Victoria Shipyards

THE LEADING SHIP REPAIR AND MODERNIZATION FACILITY ON CANADA’S WEST COAST, OFFERING FULL-SERVICE DRYDOCKING AND WET BERTH REFIT SERVICES FOR ALL TYPES OF VESSELS.

Its strategically located facilities, deep technical expertise, a reputation for quality, on-time project delivery and outstanding customer service make Victoria Shipyards a sought-after partner to government and commercial fleets, in Canada and around the world. Victoria Shipyards specializes in complex projects up to complete vessel conversions. It is an integral part of the Canadian Navy frigate and submarine maintenance programs, with its highly specialized and experienced team providing critical maintenance on Canada’s Halifax-class frigates for over 20 years and in-service support for its Victoria-Class submarines for over a decade.

Vancouver Drydock

FULL-SERVICE VESSEL SERVICE AND REPAIR FACILITY WITH A REPUTATION FOR QUALITY, ON-TIME DELIVERY, FLEXIBILITY AND OUTSTANDING CUSTOMER SERVICE.

Located on the north shore of Canada’s largest port, Vancouver Drydock plays an integral role in supporting the vessels that serve Vancouver and the Pacific Northwest. Whether performing scheduled hull maintenance, replacing worn equipment, or fabricating and installing specialized machinery to enable a vessel’s mission, the skilled team of over 200 complete maintenance, repair and refit on over 50 projects per year on vessels ranging from small tugs, ferries, large freighters, Coast Guard vessels and cruise ships.

Our Economic Impact

Accounting for direct, indirect and induced contribution, Seaspan’s NSS-related shipbuilding activities together with repair, refit and maintenance activities have contributed $5.7 billion to GDP and 7,330 annual jobs in Canada over the 2012-2022 period. Through 2035, this is projected to increase to $20.7 billion and 10,938 jobs annually.

Recent Updates

Recent Shipbuilding and Ship Repair Press Releases

25 April 2024

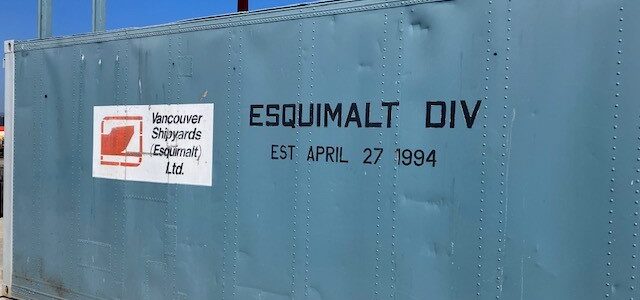

Seaspan celebrates 30 years of ship repair in Victoria

April 25, 2024 – Victoria, BC – Seaspan is celebrating the 30th anniversary of its Victoria Shipyard – a leading ship repair and modernization facility on…

Read More26 March 2024

Seaspan Shipyards Progresses to Next Phase of Designing and Building Multi-Purpose Vessels for the Canadian Coast Guard

March 26, 2024 – North Vancouver, BC – Seaspan Shipyards (Seaspan) has been awarded the Construction Engineering (CE) and Long Lead Items (LLI) contracts for the…

Read More8 February 2024

Seaspan Shipyards completes ‘Prototype Block’ for Canadian Coast Guard’s future Polar Icebreaker

February 8, 2024 – North Vancouver, BC – Seaspan Shipyards (Seaspan) has successfully completed construction of the ‘Prototype Block’ for the Canadian Coast Guard’s (CCG) Polar…

Read More